|

Aura Nema has always shrewdly intertwined tradition with innovation to acquire the technical, artistic and human capital that shapes its vision of beauty. From the selection of raw materials to the finishing, each creation embodies the world of craftsmanship in its most noble and accomplished form. |

|

|

|

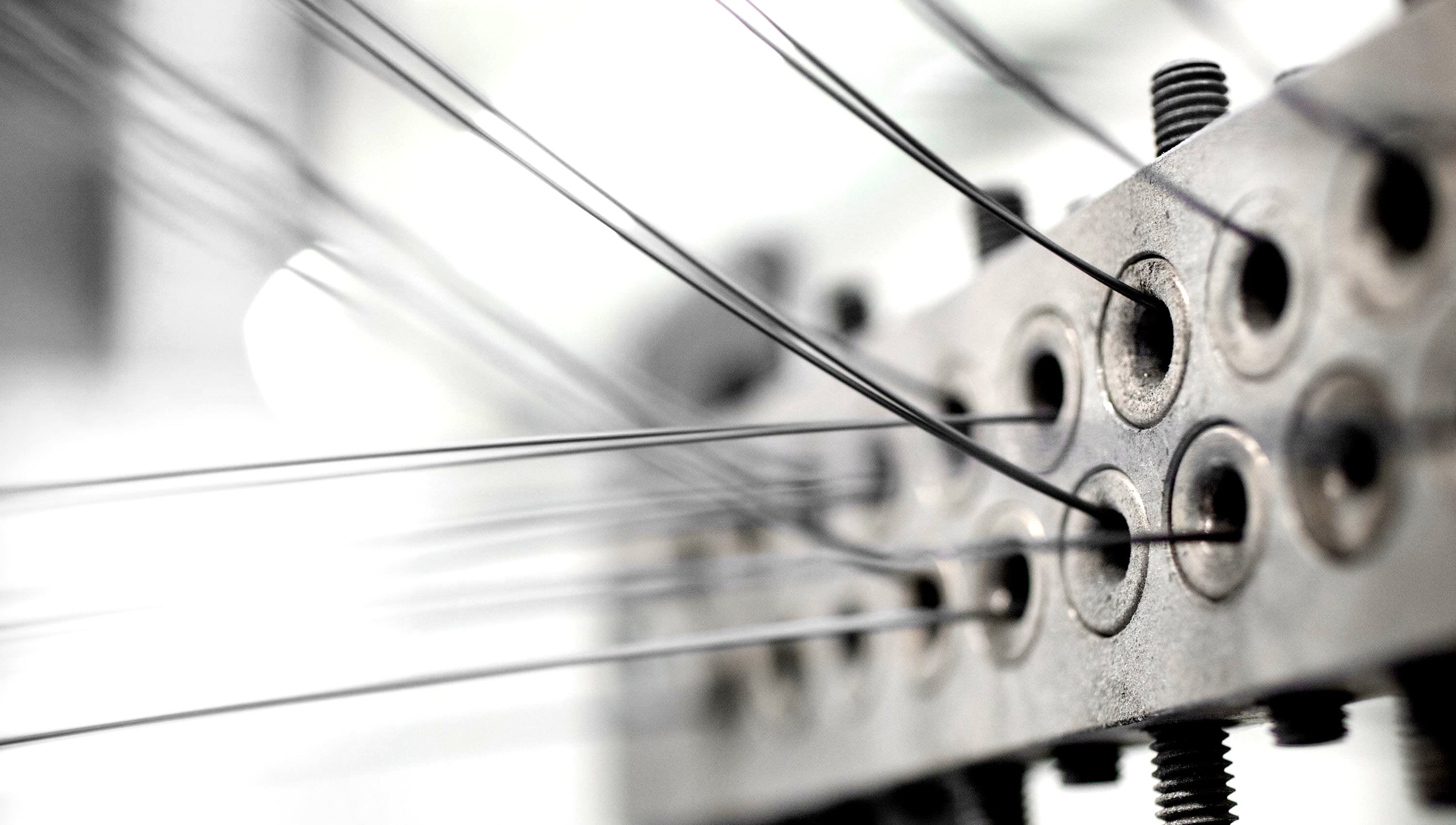

From raw silver, our silversmiths create a wire with a rolling mill. Too large a diameter to be used as it is, this wire is manually tapered by alternating several steps of heating, pickling and drawing. |

|

|

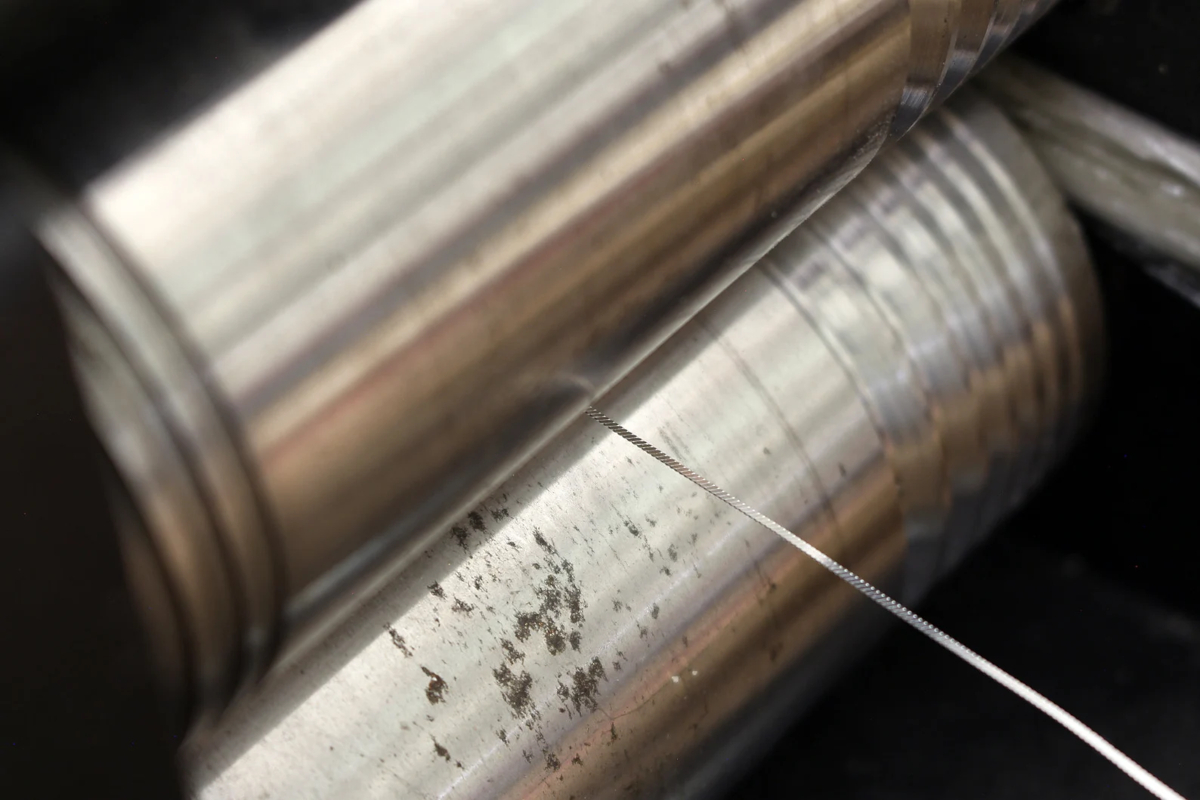

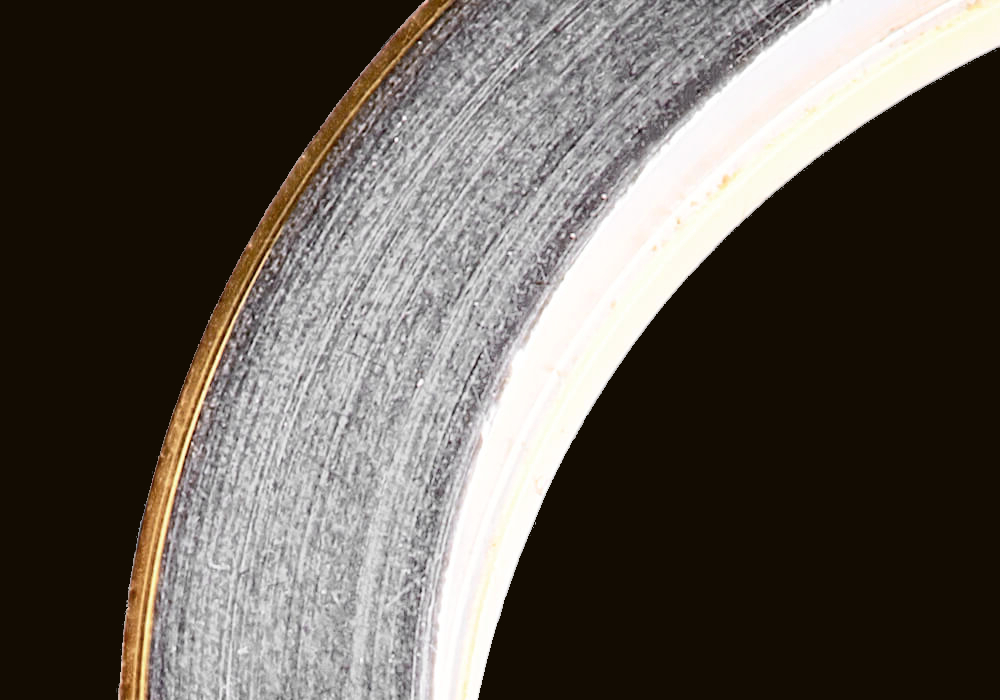

| Then comes the delicate twisting of the round wire and flattening in silky ribbon. Thickness is less than half a millimeter. |

|

|

Thanks to this long and meticulous preparatory work of the wire, a remarkable texture effect is given on the material, conferring light and movement effects on the front and back of the pieces. |

|

|

|

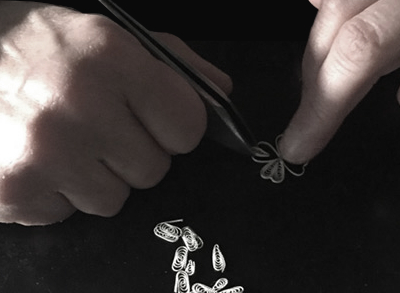

The thin ribbons are shaped one by one into graphical twists and twirls to form precise patterns. Small volutes are carefully added and thus transform a simple drawing into an exceptional precious metal lace. From the perfect micro-welding of each volute depends the solidity of the whole final creation. |

|

|

|

Essential component of the finishing of the work, the manual polishing makes it possible to obtain a state of surface of high quality. Different methods are used depending on the surfaces being worked on. The interior of the volutes requires precision polishing using a cotton thread impregnated with polishing paste. |

|

|

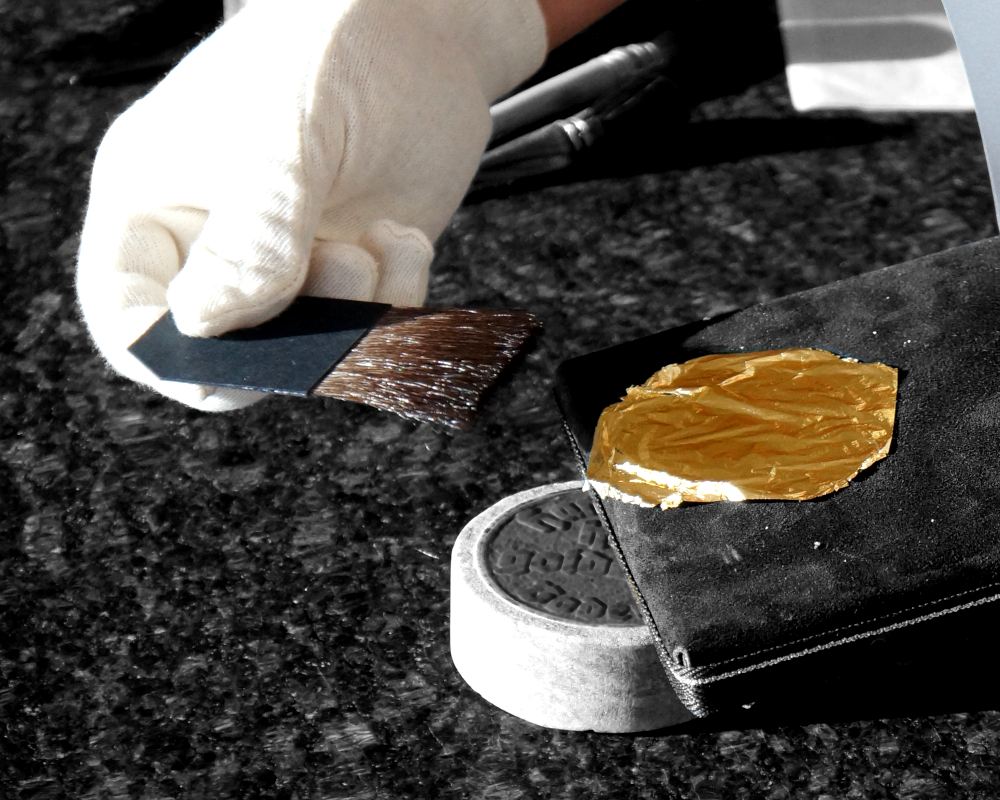

| After a final cleaning, the silver jewelry is prepared to receive several layers of gold.

Gold plating involves a certain number of precision processes, skilfully mastered to ensure a perfect and regular finish. From traditional gilding with pure gold leaf to dipping the pieces in gold baths, it is with great care that these processes are carried out for a sumptuous finish. |

|

|

| Gold plating thickness is controlled systematically to guarantee the highest possible standard of quality. During the final check, aesthetic appearence of the creation is verified one last time. |

|

|

| From melting raw metals to checking the final work, 60 to 80 steps are required, all performed by hand. A minimum of five years of experience are required in order to master each technique in compliance with the quality requirements and elegance criteria of the Aura Nema Maison. |